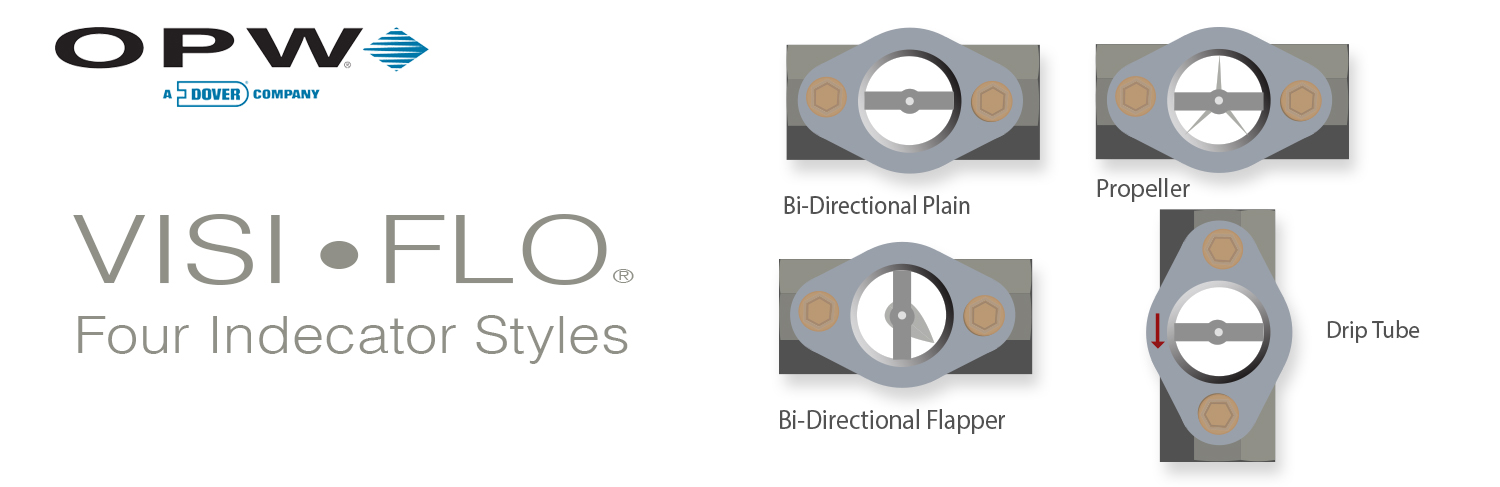

VISI-FLO® Sight Flow Indicators

Dollar for dollar, sight flow indicators are the most cost efficient and effective way to visually monitor the flow of fluids and to determine where, if any, problems exist at certain points along the industrial process line.

OPW has been manufacturing sight flow indicators for over 60 years. Our experience has led to many innovations in design and manufacturing, making VISI-FLO® the most thoroughly-engineered sight flow indicator on the market.

VISI-FLO’s are available in three series: the Standard 1400 Series, the 1500 High-Pressure High-Temperature Series and the 1600 OEM Series.

Standard Features

Exclusive 3-Year “No-Leak” Guarantee –

VISI-FLO’s innovative radial seal creates a constant and uninterrupted sealing force between the body and outside diameter of the glass lens. This sealing method provides a longer lasting and better seal than conventional flat seals.Maintenance-Free Design –

VISI-FLO’s unique, bolt-on-body design requires no special maintenance or torquing sequence be followed to prevent leaks. This results in a safer, more reliable sight flow indicator than those units using tie rods to fasten lens and seal to body.Dimensionally Interchangeable –

“FJP” Flanged VISI-FLO's feature end-to-end dimensions that match Jacoby-Tarbox and Penberthy and other manufacturers’ units. “FJP” units are available in 3/4", 2", 3", and 4".Shipment Within 48 Hours on Most Items

OPW Engineered Systems offers a complete line of sight flow indicators, including the popular VISI-FLO® series.

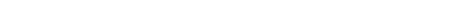

Four Indicator Syles

Drip Tube – Ideal for gravity, extremely low or intermittent flow. Keeps product from dripping on the glass. Assures constant see-through for vertical lines.

Propeller - The best way to show flow of opaque liquids. Ideal for observation at a distance. Flow from right to left is standard. Specify if left to right flow is needed. Not recommended for flow rates above 100 GPM.

Bi-Directional FLapper- This indicator points in either direction to show you at a glance which way the liquid is flowing.

Bi-Directional Plain- When the color and clarity of your liquid are of prime importance.

Applications

One of the key strengths of sight flow indicators is their remarkable versatility. For example, they can be used:- In a variety of industries.

- To monitor and verify fluid flow through filter, cooling, intake/outlet pumping lines, as well as numerous other industrial processes.

- For troubleshooting or as backups for meters, switches, process indicators and other control devices.

- Power Plants

- New Power Plants: Sight flow indicators monitor the flow of critical fluids, such as lubricants pumped to turbines in hydro-electric generators and water in cooling lines.

- Older Power Plants: New, more reliable sight flow indicators replace aging models (and additional indicators are also deployed) during upgrades.

- Waste Water Treatment

- VISI-FLO® sight flow indicators visually monitor the filtering process.

- The most common point of installation: second stage aeration tank pumping lines.

- The purpose: verify sludge removal to ensure efficient aeration.

- Petroleum Industry

- Sight flow indicators visually monitor drilling pump operations. VISI-FLO® is used to show dirty fluidsbeing pumped from a down-hole hydraulic cleaning process.

- Should the indicator stop, this is a signal to the operator that the system is not cleaning properly and needs corrective action.

- Chemical Industry

- Paint and Varnish Processing Plants: VISI-FLO® sight flow indicators are used to notify operators when filters become clogged. Any drops in flow rate or discoloration of blended resins that pass through the press are indications that new filters are needed.

- Distilling Operations: Sight flow indicators are used to gauge color and clarity of fluids. An amber fluid color indicates proper distillation; a brown-toblack color signals the process has been disrupted and requires corrective action.

- Refineries: Sight flow indicators are used to monitor the drainingof waterfrom the bottom of storage tanks. The visual presence of oil in the indicator is a signalthat the water is completely drained.

- Manufacturing

VISI-FLO® sight flow indicators are used in a variety of manufacturing applications, including, for example, to monitor:- The draining of hydraulic oil from nitrogen charged accumulators in die casting machine manufacturing facilities.

- Proper coolant flow, which is so vital to the operation of welding machines.

- Efficient filtration of process fluids.

- OEM Markets

VISI-FLO® sight flow indicators are used in an array of OEM applications, including, for example:- Compressor manufacturers install them on their products so end users can monitor the flow of water to compressor heads while in operation.

- Degreasing and defluxing equipment manufacturers use them to monitor recirculating solvent in cleaning operations and, thus, determine efficiency of the distillation/recovery process.

- Evaporators and filtration system manufacturers use them to monitor color and clarity of fluids in outlet lines and to confirm proper intake of fluids on inlet lines.

- Other potential uses:

- As a back-up to electronic equipment; seeing is believing.

- On boiler feed lines

- With steam traps to know when a clog is developing

- In a blending operation to see color and clarity

- On cooling tower lines

- In distillation processes

- On paper machine condensate lines

- On water cooled air compressors

- At the bottom of a vessel to see if it is empty

- On lubricating lines of machine bearings

- On aircraft refueling trucks

- In solvent recovery systems

- On desalination equipment

- Potentially, anywhere that fluids are used, VISI-FLO can be used!